Product

Home > Product > SATAKE > Prefabricated Environment Test Chambers

Prefabricated Environment Test Chambers

Satake Prefabricated Environment Test Chamber

Sataka creates its quality products with state-of-the-art production technology, insisting on uncompromising quality control in an immaculate work environment.In key sectors such as electronics, biotechnology, and the automotive industry, numerous materials and products are subjected to stringent environmental tests in order to satisfy strict standards for quality, function and durability.

Satake is a partner with industry in this environmental testing and the excellence it assures.

Satake environmtntal test chambers enable extremely precise simulation for any given set of anticipated environmental conditions.

As our motto says, we are committed to "building total satisfaction into products customers can trust."Our quality control is comprehensive, with customer satisfaction as its criterion.

We are confident that Satake technology - and reliability - can meet any demand.

The Satake Prefabricated Environment Test Chamber is highly sophisticated measuring tool.

Several various are available, including temperature/humidity chambers, temperature chambers, low temperature chambers and ultra-low temperature chambers.

Each prefabricated environment test chamber is a product of Satake's technological expertise and numerous years of experience in the field, and all feature high stability and accuracy.

Features

Control Devices Incorporating Electronics

[1]Temperature(humidity) controller, equipped with a highly visible , easy-to-monitor LCD indicator, executes a range of functions in addition to temperature and humidity control.[2]Temperature(humidity) controller, equipped with LCD indicator, can automatically select the proper instrument for cooling, humidification, or other environmental modification required to match the control temperature or humidity.(When program-control is active)

[3]The system directly sets the relative humidity; therefore, indications or records can be expressed by relative humidity.

Energy Savings

[1]By employing a dispersed(multiple-unit) refrigerator arrangement, a nearly 20% energy saving can be obtained relative to single large-capacity refrigerator configurations.Back-up capability is another of the system's merits: should one of the multiple refrigerator units fail, operation continues with the other refrigerators.[2]Because refrigerators are inverter controlled, the system realizes an energy savings of 20% or more.

Temperature Regulators Offer Superb Accuracy

[1]With the adoption of a large blow-in area and restricted air speed within the chamber - not to mention the reducedrange of temperature and humidity variation andrich air volume - the system attains high precision in temperature distribution.

[2]The air conditioner, designed for room installation, requires very little floor space, thus minimizing heat loss.

[3]The boiler-type humidifier is easy to maintain and less susceptible to the build-up of scale and other impurities.

[4]Satake's original "Level Method" water supply never interferes with the precise control of humidity.

Practical Application Foremost in Test Chamber

[1]Rationalized design, employing hard urethane foam panels, makes the chamber compact, while insertion of a reinforcing member in the floor increases the withstand load.[2]The door is provided with a large observation window, with heating wire incorporated to prevent fogging.It offers good visibility excellent hinge durability and locking mechanism safety.

[3]Stainless steel plate is used for the interior face of the test chamber, while ivory colored vinyl chloridecoated steel plate is employed for the external face.Its facing makes the chamber suitable for any location, and offer unsurpassed durability andcorrosion resistance.

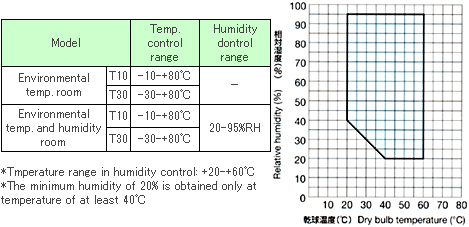

Standard Temperature and Humidity Control Ranges

| Standard Accessories

|

Model identification SL/Denotes the prefabricated room H/H:Environmental temperature and humidity room T:Environmental temperature room 15/Denotes the size of the room (With suffix "L" added for low-temperature specifications) 10:1900W×1900Dmm 15:2800W×1900Dmm 20:3700W×1900Dmm 25:4600W×1900Dmm 30:3700W×2800Dmm 40:4600W×2800Dmm 50:4600W×3700Dmm 10/Denotes the temperature range 10:-10~+80℃ 30:-30~+80℃ R/Denotes the category of instrumentation R:Temperature(humidity) controller + Temperature(humidity) recoder P:Programmable temperature(humidity) controller PR:Programmable temperature(humidity) controller + Temperature(humidity)recorder |

Optional Items

|

1-4 of 4

Electric Refrigerator Testing Device

Environment Test Chamber for Room Air Conditioners